Previous ASME Award Winner

Recent Departmental Runner Up Awards

Capstone Design Projects

Animal Care Processing Project (ACCP)

2024-2025 - Spring

Team: 42

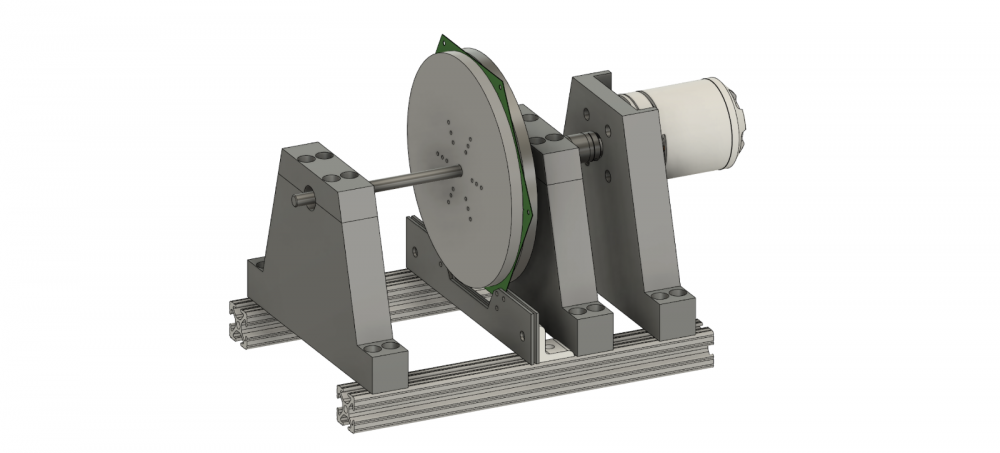

Unmanned Aerial Systems Hybrid Powertrain Testbed

2024-2025 - Winter

Team: 3

Team Members

Daniel Cruz-Espada

Jason Holtkamp

Joud Bukhari

Kenneth Su

Shivharsh Kand

Ziad Gari

Jacobs Hall Clock Revival

2024-2025 - Spring

Team: 33

Team Members

Jonathan Dela Cruz

Irving Ding

Fatima Fazli

Fernando Gochicoa

Lacey Potter

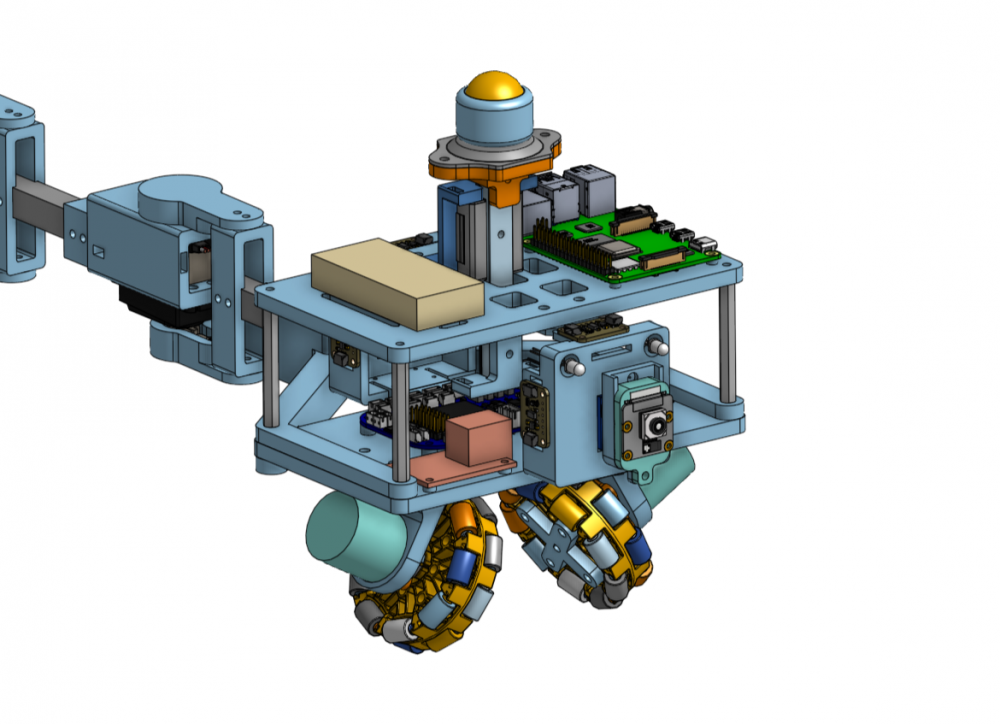

Random Positioning Machine 2.0

2024-2025 - Spring

Team: 31

Quantum Engineered Nano Device

2024-2025 - Spring

Team: 4

Team Members

Scott Ceklarz

Kalie Garcia

Satchin Narasimhan

MRI Stereo

2024-2025 - Spring

Team: 5

Antibiofouling System for Moored Marine Instruments

2024-2025 - Spring

Team: 23

Triton-Ai Racquet Ball Launcher Magazine and Control

2024-2025 - Spring

Team: 34

Regenerative Trailer Braking System

2024-2025 - Spring

Team: 3

Solar Wind Tunnel

2024-2025 - Spring

Team: 32

Team Members

Benjamin Marsden

David Bori

Max Gonsalves

Rachel Gillespie

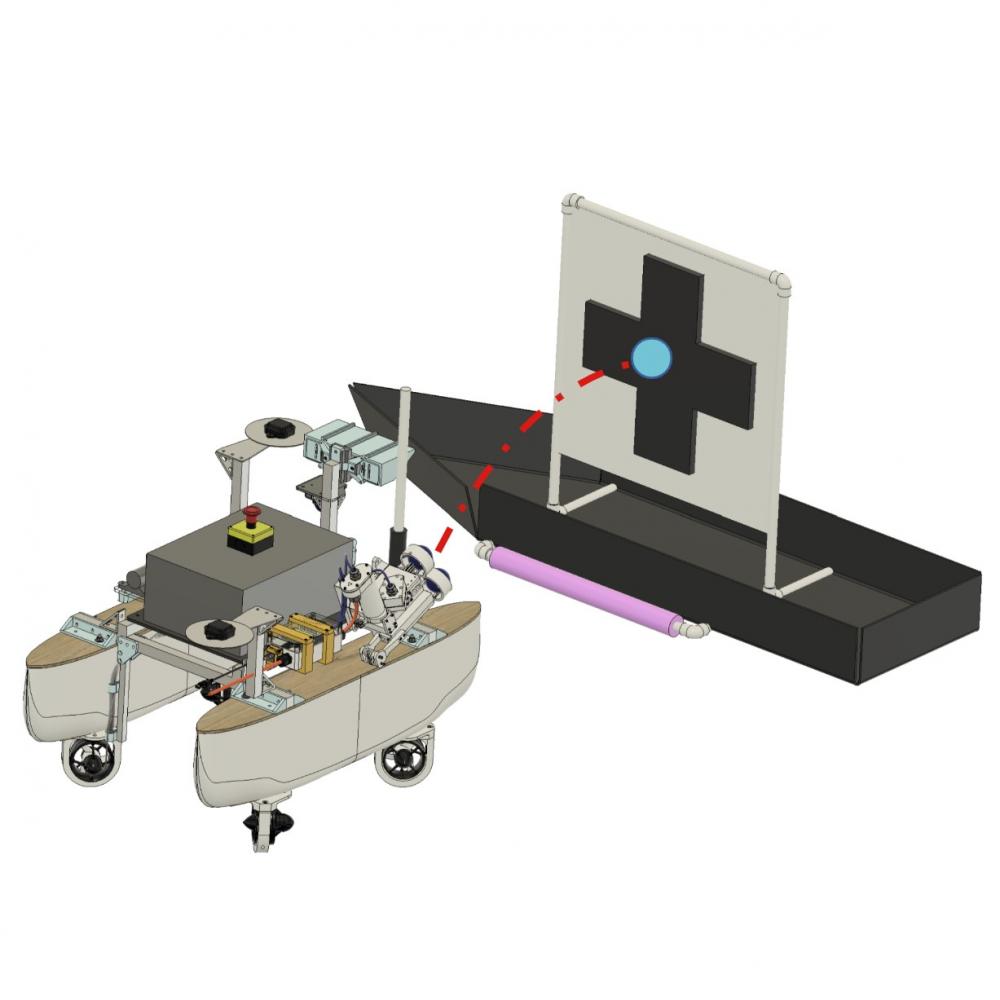

Manual In-Pipe Robot Surrogate for Autonomy Development

2024-2025 - Spring

Team: 18

SomnoStay - A Novel Oral Appliance for Obstructive Sleep Apnea

2024-2025 - Spring

Team: 7

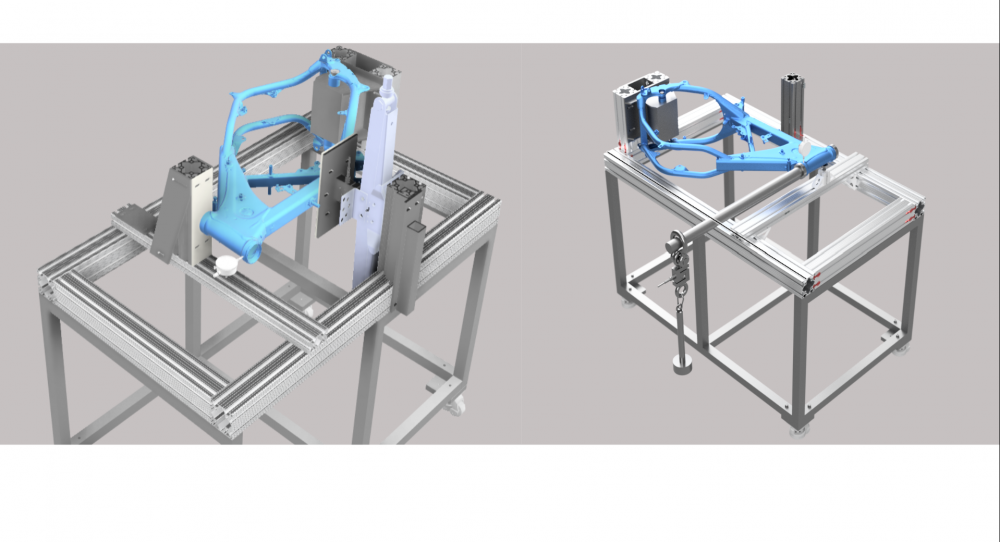

ShockE Frame Stiffness Test Fixture

2024-2025 - Spring

Team: 19

Carbon Blade Carbon Capture

2024-2025 - Spring

Team: 15

Team Members

Ian Cosgrove

Charlie Frank

Juncheng Li

Alexandra Rodriguez

Konrad Stromayer

Automated Cognitive Touchscreen Training System for Mice

2024-2025 - Winter

Team: 8

GA - Foam Shell Culling Station

2024-2025 - Winter

Team: 1

Team Members

Tobin Boshaw

Matthew Pope

Collin Huang

Samuel Hasegawa

Kenny Ochoa

Brandon Lopez

Endovascular Device for Rapid Blood Clot Removal

2024-2025 - Winter

Team: 12

Sample Throughput Optimization for Thermal Desorption Spectroscopy

2024-2025 - Winter

Team: 15

Team Members

Ethan Greene

Jamie Lee

Saul Rios

Leo Serbinov

Vedanth Talla

Brayden Wong

Acoustic Modem Integration onto Wave Glider USV

2024-2025 - Winter

Team: 16

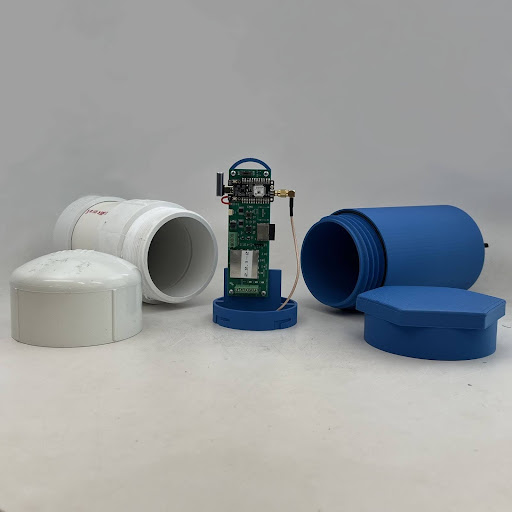

Outdoor Low Power Measurement Equipment Enclosure (ENTS Enclosure)

2024-2025 - Winter

Team: 11

Team Members

Fayza Elshafie

David Fisher

Michael Gonzalez

Benny La

Elliot Snyder

LightLok - Burn Prevention

2024-2025 - Winter

Team: 13

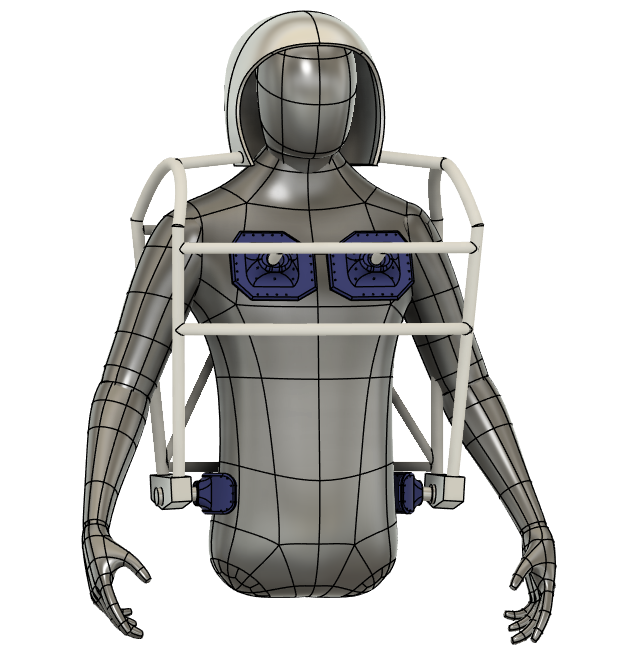

Halo Helmet Platform

2024-2025 - Winter

Team: 9

This project introduces a helmet-integrated roll cage that redistributes impact forces away from the head and neck. Anchored to the upper body via a harness, the system disperses forces more effectively, reducing the risk of traumatic brain and spinal injuries.

Endoscopic Multiload Clip Applier

2024-2025 - Winter

Team: 5

KangaMove Parental Skin-to-skin Contact Support

2024-2025 - Winter

Team: 7

Automated Tracheal Cuff Pump

2024-2025 - Winter

Team: 6

Flow Enabled Energy Generation Device

2024-2025 - Winter

Team: 4

Team Members

Ashley Campbell

Maime Grace Barnard

Gabrielle Scott

Markus Gokan

Justin Kwak

UCSD Med Low Cost Microsurgery Instruments

2024-2025 - Spring

Team: 14

Material Transfer Cleaning

2024-2025 - Winter

Team: 2

Automated Graphene Transfer

2024-2025 - Winter

Team: 14